Hot chamber die casting

During

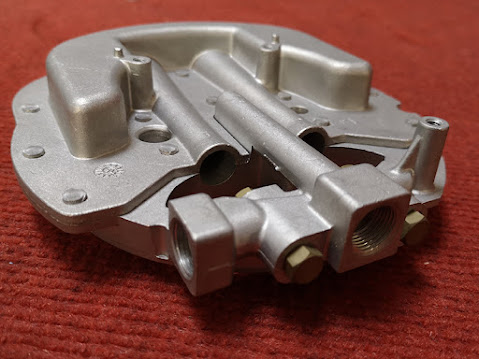

the process of hot chamber Metal Die

Casting, the metal die casting machine contains the necessary equipment

required for heating the metal to a molten state. As it is a self-contained

system, it is much faster than the alternative but it is only suitable for a

selection of casting materials, which includes zinc, tin, and lead alloys.

Cold chamber die casting

The

cold chamber die casting process may need to use a separate furnace to heat the

metal. This slows down the process, as the molten metal can be brought to the

die casting machine with the help of a ladle. However, because a separate

furnace is much more powerful than a hot chamber die casting machine, metals

with high melting points can be cast. For aluminum casting, this method is

suitable and is preferred by Metal Die Casting Company.

The

metal die casting process typically proceeds as follows regardless of whether a

hot chamber or cold chamber machine is used:

- Shakeout

- Filling

- Ejection

Mold preparation

During

mold preparation, the interior surfaces of the two die halves have to be coated

with a lubricant so that it can facilitate ejection once the castings are

complete. With locking pins, the die halves can then be closed and secured.

Using a pressure system, the filling of the mold can be achieved. In both cases, the result is a molten metal that is being forced into the mold cavity via the sprue. In a hot chamber, high pressures up to 35 megapascals and in a cold chamber 140 megapascals make sure of a fast and comprehensive filling, which in turn leads to consistent cooling that prevents uneven shrinkage and consequent part deformation. During cooling, pressure is highly maintained.

Follow us on Twitter

No comments:

Post a Comment