Ever wondered how metal toy soldiers were prepared or how some items turn up to be shaped as they are? Manufacturers never mold these shapes as they do for clay pots; instead, the usual process is die casting.

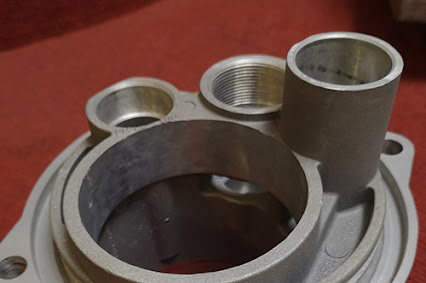

Die casting is a process in which metal parts are produced by using molds or dies of different shapes. Here, under the high-pressure, molten metal is poured into a mold cavity to which it takes its shape unless the cavity is provided allowances for the drafting, molding, or machining of the finished product by the pattern maker. Alloys that can be used usually differ from zinc and copper to magnesium, lead, and even tin and pewter.

One of the main processes used is by having the metals in high pressure. In casting among different other metal alloys this is the most common way which represents about 50% of all production. On the other hand, the low method is used only about 20% of the time for only special products. Its usefulness increases within time. Few other methods are gravity die casting - which constitutes the remaining percentage of production with only a little less left for recently introduced processes - squeeze die casting and vacuum die casting.

Aluminum is a lightweight alloy that for different shapes and even thin walls has high stability and it also shows good resistance and mechanical properties. The strength of aluminum is seen in high temperatures by the Die Casting Supplies and it has a lot of usage. Every metal alloy has its special way and this does not go a different way with aluminum.

In this process, the mold is not always destroyed. It is even used to create a figure closer to the finished product itself. Other manufacturers who use aluminum parts keep the mold permanent as the aluminum itself would provide outer protection. The use of the process of cold chamber process for aluminum is due to their high melting points.

It is necessary to select trusted die casting manufacturers who for the advantage of the part or product intend to make know the best way to customize the production process. Follow us on Twitter

No comments:

Post a Comment