Die casting is a process in which metal parts are produced by using molds or dies of different shapes. This Custom Metal Casting method takes benefit of the fact that metal softens under very high temperatures thus making it possible for manufacturers to alter it into any shape. Therefore, to smelt the metal into dies of different sizes and forms the process involves several apparatuses.

Even with items that have small dimensional limitations, it can develop better results. Objects that are built through the process of die casting have smoother surfaces that practically do not require any polishing. Due to the reduced amount of finishing costs, production using this process is not only speedier but is also less expensive.

Manufacturing corporations can generate the same items without having substantial variations in dimensions and designs as dies are reusable. Thus, you can apply it to other metalworking businesses, such as vehicle and toy development.

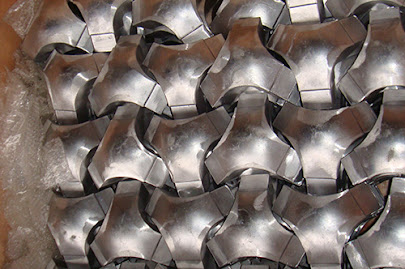

Custom Metal Casting China consists of four significant phases. The first step is involved in preparing and loading the metal by removing g grime and moisture on the apparatuses and before molding, they preheat the material. To allow straightforward elimination of solid objects later on the dies may also be applied with lubricant. The next step is melting the metallic with the help of industrial burners of suitable dimensions and functions.

To make sure that temperature stability is necessary for refining and treating the molten metal the different kinds of metal melting equipment are also closely monitored by manufacturers. The third phase involves transferring the molten material to the custom-made dies where substantial pressure and temperature enable the metallic so that it can follow the precise shape of the mold.

To

entirely harden the metal, the dies need to be allowed to cool down; even so,

if Custom Metal Casting Manufacturer is required to complete

the task faster. For quick solidification, cold water can be sprayed on the

casting. Then the dies are opened and the cast is finally removed. In die

casting the most important thing is having the proper pressure and temperature

that you can only get with the best burners industrial plants can have. Follow us on Twitter

No comments:

Post a Comment