The

steps followed in Sand Casting Foundry are:

Mold creation

Creating

the mold for the Sand Casting is the

first step. Around the pattern, the sand is packed which is a replica of the

external casting shape. The casting forming cavity remains. The bottom and top

halves of the mold are known as the drag and cope respectively.

Preparing and clamping the

mold

It must be prepared for the molten metal to be poured once the mold has been made. To help with the removal of the casting, the surface of the mold cavity is first lubricated and the mold halves are securely clamped and closed together. To prevent the loss of any material, the mold halves must remain securely closed.

Molten metal pouring into

the mold

Through

a gap, or gating system leading from the casting cavity to the outside of the

mold, molten metal is poured into the mold in the Sand Casting Foundry. To secure the two halves together, you can

see jackets and weights on these molds. Into this mold, molten aluminum is

being poured.

Allowing the metal to cool

Once

it enters the cavity, the molten metal poured into the mold will begin to

solidify after getting cooled. The final shape of the casting is formed when

the entire cavity completes the metal solidification process and is filled.

Until the proper cooling time has elapsed, the mold can’t be opened.

Hardened Casting Removal

from mold

The

sand mold can simply be broken after the solidification time has passed and the

casting is removed. By a vibrating machine that shakes the casting and sand out

of the flask, this step is performed typically. For reuse, the sand is

reconditioned. The casting will likely have some oxide layers and sand stuck to

the surface once removed. To remove the remaining sand, Shot blasting is used

sometimes.

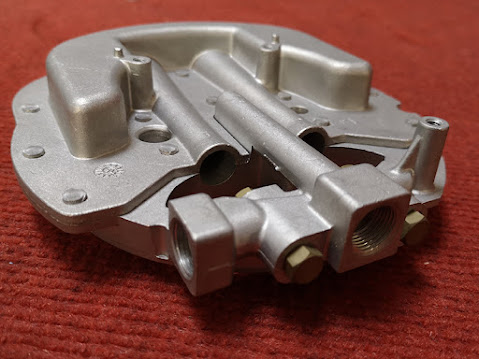

Polishing & finishing

the final product

The casting may be finished or polished to offer a functional surface for its final application based on the intended use of the final Sand Casting Products. To remove the roughness left on the surface of the casting, Surface finishes of varying grades can be applied. Castings or raw castings ready for use are offered. This has been machined and heat treated. Secondary operations such as finishing and powder coating can also be added.

Follow us on Facebook