The

introduction of die casting aluminum was in 1914, when aluminum was invented

for the first time. However, die casting was developed way back in the 1800s, still

only alloys of various compositions of tin and lead were used. However, in this

process aluminum casting revolutionized the whole concept.

Proper

designing for quality Die Casting:

In

getting the right Casting Aluminum products it is important to have a great

team of designers who will take proper care to collaborate with casting

experts. In order to get a quality final product eventually this is an

essential prerogative during the early stages of designing. During the tooling

and the production phase in Aluminum Casting this helps in cutting down

unnecessary expenditures. Designing and proper planning have always resulted in

proper execution, which in turn provides products that are of quality and have longer

shelf life. These are then delivered by Aluminum Casting Supplier.

Aluminum

Die Casting and Cold Chamber Machines:

Usually

for die casting aluminum cold chamber machines are used and aluminum comes with

high melting points. Into a cold chamber, or cylindrical sleeve the process

involves pouring molten metal. This can be performed either manually by a hand

ladle or by an automatic ladle. The next step is sealing the cold chamber port

and at high pressures with the help of a hydraulically operated plunger forcing

metal into the locked die.

Role

of Automated machines in Die Casting:

These

days Die casting aluminum have improved a lot and automated quality control

have been replaced by manual operations. Today in die casting method there are

many different types of machines utilized, which in return makes your work

easy, save your time and increase your productivity.

These

days there are microprocessors just for adjusting Casting machines and assuring

steady castings. Through these machines you can obtain metal velocity, shot rod

position, hydraulic pressure and other data.

In

Die Casting Aluminum is Ideal:

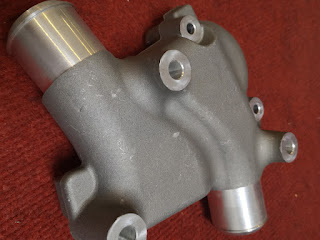

In die casting aluminum industry, the main reason of its popularity is for its lightweight and anti-corrosion properties. Apart from that, for complex shapes and thin walls this metal possesses high dimensional stability. Thing that made aluminum die casting a much-preferred option these days by Aluminum Casting Manufacturer is the High thermal and electrical conductivity, as well as ability to withstand high temperatures.

Follow us on Twitter

No comments:

Post a Comment